The Science Behind Thermally Broken Windows

Thermally broken windows offer a significant upgrade from traditional windows, providing superior insulation. This improved performance comes from a strategically placed interruption within the metal frame, known as a thermal barrier. This barrier effectively minimizes heat transfer between the inside and outside of the frame, impacting both energy efficiency and overall comfort.

How Thermal Breaks Combat Heat Transfer

The basic principle of a thermal break is simple: disrupt the flow of heat. Think of a metal spoon in a hot cup of coffee. The handle quickly heats up because metal is an excellent conductor of heat. A thermally broken window frame, however, uses a less conductive material within the frame to interrupt this flow. This barrier acts as insulation, minimizing heat transfer and helping maintain a consistent indoor temperature year-round.

Materials Used for Thermal Barriers

Various materials, each with its own unique properties, are used to create these thermal barriers. Polyamide, a type of nylon, is often chosen for its strength, durability, and excellent thermal insulation properties. Polyurethane, a rigid foam, provides even greater insulation. A less common, but highly effective material is fiberglass, known for its strength and low thermal conductivity. These materials are strategically positioned within the frame to disrupt the continuous path of metal and impede the flow of heat.

The Growing Market for Thermally Broken Windows

The increasing emphasis on energy efficiency is driving significant growth in the market for thermal break frames. Thermally broken windows are, in fact, essential for maximizing energy savings in buildings. The global market for thermal break frames is projected to reach $4247.6 million by 2033, growing significantly from $2665 million in 2025. This growth is fueled by the rising demand for sustainable and energy-efficient building materials. Find more detailed statistics here

Evolution of Thermal Break Technology

Early thermal breaks were fairly simple, but advancements in technology have led to sophisticated designs. These newer designs often incorporate multiple chambers and specialized materials to further optimize thermal performance. For instance, some thermally broken windows use a “pour and debridge” method, injecting insulating material into the frame cavity to create a highly effective barrier. This constant evolution has resulted in windows that drastically outperform traditional windows, making them increasingly important in modern construction.

Transform Your Energy Bills With Thermal Breaks

Thermally broken windows offer a significant leap forward in energy efficiency. But how do these windows translate into tangible savings? Understanding the real-world impact is key. Let’s explore how thermal breaks minimize energy loss and contribute to a greener future.

Understanding the Impact of Thermal Bridging

Traditional window frames, particularly metal ones, can act as conduits for heat transfer. This thermal bridging allows heat to escape during winter and enter during summer. This constant heat flow makes your HVAC system work harder, resulting in higher energy consumption and bigger bills. Thermally broken windows address this directly, minimizing heat transfer and maintaining comfortable indoor temperatures.

Quantifying the Energy Savings

The effectiveness of thermally broken windows is measurable through U-values and R-values. The U-value measures how well a window prevents heat loss, while the R-value indicates its resistance to heat flow. Lower U-values and higher R-values indicate better insulation. The difference in these metrics between standard and thermally broken windows can be substantial, leading to significant savings on heating and cooling costs. You might be interested in: Upgrade Today: Energy-Efficient Window Replacement Solutions

Let's delve into a direct comparison to illustrate these improvements:

To better understand these performance differences, consider the following table:

Energy Performance Comparison: Standard vs. Thermally Broken Windows This table compares the energy performance metrics between traditional windows and thermally broken windows across different climate zones. We'll use approximate values to illustrate the potential improvements.

| Performance Metric | Standard Aluminum Windows | Thermally Broken Windows | Improvement Percentage |

|---|---|---|---|

| U-Value (W/m²K) | 5.0 | 1.5 | 70% |

| R-Value | 0.2 | 0.67 | 235% |

As this comparison reveals, thermally broken windows offer significantly improved insulation, leading to the substantial energy savings discussed earlier.

Real-World Savings Across Climate Zones

The financial benefits of thermally broken windows depend on factors like climate, building size, and energy prices. However, studies show these windows can lead to substantial annual savings. In colder climates, homeowners can see a 10-25% reduction in heating bills. In warmer regions, savings on cooling costs can be equally impressive. This translates to real money saved, making thermally broken windows a smart investment. For further insights into energy efficiency principles, especially regarding skylights, see: energy efficiency of skylights.

The Growing Market for Energy Efficiency

The advantages of thermally broken windows extend beyond individual homes, contributing to broader sustainability efforts. The global energy-efficient windows market, encompassing thermally broken windows, is growing rapidly. It’s projected to rise from $12.53 billion in 2024 to $13.26 billion in 2025, a CAGR of 5.9%. This growth highlights the increasing global emphasis on reducing energy consumption and carbon footprints. Learn more about the expanding market for energy-efficient windows.

Reducing Your Carbon Footprint

By minimizing energy use, thermally broken windows play a crucial role in reducing greenhouse gas emissions. This lowers the carbon footprint of both residential and commercial buildings. As environmental awareness increases, the demand for sustainable building materials like thermally broken windows is expected to continue rising.

The Comfort Revolution: Beyond Energy Savings

Thermally broken windows are well-known for their energy efficiency. But their advantages go beyond simply lowering your utility bills. They significantly improve the comfort of your home or workspace. Let's delve into how these windows enhance daily living. For more on energy-efficient windows, check out this resource: Top Energy-Efficient Window Ratings for Savings.

Eliminating Cold Spots and Drafts

One of the most immediate benefits of thermally broken windows is the elimination of cold spots near windows. In homes with standard windows, these chilly areas can render sections of a room unusable during the winter months. Thermally broken windows maintain a more even temperature throughout the room. This improves both comfort and usable space. This consistent temperature also minimizes drafts, leading to a more pleasant indoor environment.

Condensation: A Thing of the Past

Condensation on windows can cause a variety of problems. These include mold growth, deterioration of the window frame, and potential health concerns. Thermally broken windows minimize condensation by reducing the temperature difference between the interior and exterior surfaces of the glass. This makes it less likely for moisture to condense on the inside of the window, protecting the window and promoting a healthier home.

The Unexpected Bonus: Sound Insulation

Beyond their thermal advantages, thermally broken windows also provide improved sound insulation. The thermal break, combined with the typical double or triple glazing, disrupts sound waves. This effectively reduces noise pollution from outside. Studies indicate that thermally broken windows can reduce noise infiltration by up to 50% compared to standard windows. This makes them a particularly good choice for homes in urban environments or near busy streets.

Market Growth Reflects Increased Demand

The rising popularity of these windows, driven by comfort and other factors, is reflected in the growth of the insulating glass window market. Valued at $14.04 billion in 2024, this market is projected to reach $19.73 billion by 2029, demonstrating a CAGR of 6.0%. Learn more about this growing market here.

Enhanced Comfort, Enhanced Living

The combined advantages of stable temperatures, reduced condensation, and soundproofing create a more comfortable and pleasant living environment. These qualities improve the overall quality of life in a home or building, making thermally broken windows a valuable investment that goes beyond simple energy savings.

Choosing Your Perfect Thermally Broken Frame

Navigating the world of thermally broken window frames can feel overwhelming with the sheer variety of materials and designs available. This section simplifies the key considerations for selecting the right frame for your project. We'll focus on material performance, thermal break types, and how to match these to your climate and architectural style. Read also: Your Ultimate Window Replacement Guide: Expert Tips & Info

Frame Materials: A Deep Dive

Four primary materials dominate the thermally broken window frame market: aluminum, steel, fiberglass, and composite. Each offers a unique set of advantages and disadvantages.

-

Aluminum: Known for its sleek, modern look and excellent strength-to-weight ratio. Aluminum frames are versatile and require minimal maintenance.

-

Steel: Exceptionally strong and durable, steel provides superior security and slim sightlines. However, it's heavier and more expensive than aluminum.

-

Fiberglass: Offering excellent insulation and durability, fiberglass resists rot and warping. While it can be pricier, it also requires minimal upkeep.

-

Composite: Combining the best of several materials, composite frames often pair a warm wood interior with a weather-resistant exterior cladding like aluminum.

To help you compare these materials, we've compiled the following table:

Thermally Broken Window Frame Materials Comparison

This table compares different thermally broken window frame materials based on key performance characteristics.

| Frame Material | Thermal Performance | Durability | Cost Range | Maintenance | Environmental Impact |

|---|---|---|---|---|---|

| Aluminum | Good | Excellent | Low to Moderate | Low | Moderate |

| Steel | Moderate | Excellent | High | Low | Moderate |

| Fiberglass | Excellent | Excellent | Moderate to High | Low | Low |

| Composite | Excellent | Excellent | High | Low | Low |

As you can see, each material offers a unique balance of performance and cost. Choosing the right material depends on your specific needs and priorities.

Thermal Break Designs: What Sets Them Apart

A thermally broken window's effectiveness hinges on the thermal break design. Here are a few key types:

-

Tubular: These use hollow tubes inserted into the frame, offering a good balance of performance and affordability.

-

Strut: Similar to tubular breaks, strut designs use solid insulating material, potentially boosting thermal performance.

-

Poured and Debridged: This involves injecting insulating material, creating a continuous, highly effective barrier.

-

Debridged: This approach minimizes metal-to-metal contact to reduce thermal transfer.

Matching Frame and Break to Your Needs

The ideal combination depends on a few factors:

-

Climate: In colder climates, highly insulating frames like fiberglass or composite with poured and debridged thermal breaks are recommended. In milder climates, aluminum with tubular breaks may suffice.

-

Architectural Style: Steel frames complement modern and industrial designs, while wood or composite frames suit traditional aesthetics.

-

Budget: Aluminum frames are generally the most budget-friendly, while steel and high-performance composites are at the higher end.

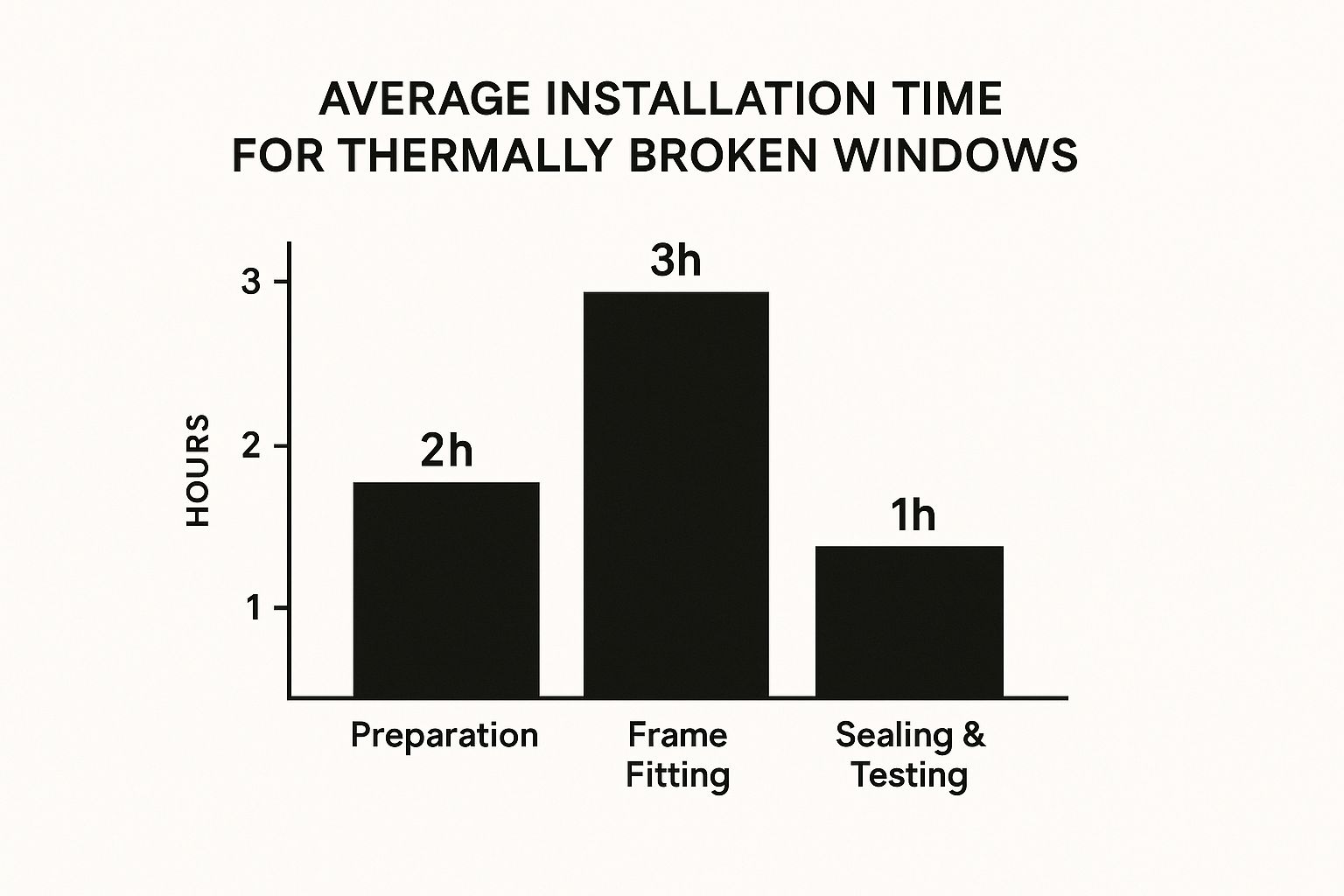

The infographic above illustrates the average installation time for thermally broken windows. The majority of the time goes into fitting the frame, highlighting the need for accurate measurements and experienced installers. The shorter preparation and sealing times demonstrate the installation process's overall efficiency.

By considering these factors and consulting with experts, you can choose a thermally broken window frame that enhances your home's comfort and energy efficiency.

The Real ROI: Making Thermally Broken Windows Pay Off

Let's talk money. When considering thermally broken windows, the initial cost compared to the long-term value is a key factor. This section will break down the elements that influence the price and show how these windows can actually save you money over time. We'll also uncover some less obvious financial perks that make thermally broken windows a wise investment.

Understanding the Initial Investment

Thermally broken windows typically cost more upfront than standard windows. Several factors contribute to this price difference. Specialized materials, like polyamide or polyurethane, are used for the thermal break, increasing the cost. The manufacturing process is also more complex, involving additional steps and specialized equipment.

Furthermore, the inclusion of energy-efficient glass, such as double or triple glazing with low-E coatings, adds to the initial expense. The frame material also matters. Options like steel or fiberglass often come with a higher price tag than standard aluminum.

Calculating the Payback Period

While the initial cost is higher, thermally broken windows offer substantial long-term savings through reduced energy consumption. By minimizing heat transfer, your heating and cooling systems don't have to work as hard, leading to lower energy bills.

The exact payback period – the time it takes for energy savings to offset the initial cost – depends on several factors. Climate, energy prices, and the specific window's performance all play a role. However, many homeowners see a return on their investment within 5-10 years. Learn more in our article about Understanding Window Energy Efficiency Ratings for Better Homes.

Hidden Financial Benefits

Beyond energy savings, thermally broken windows offer other financial advantages. Their increased durability means they last longer, reducing the need for frequent replacements. Some regions offer tax incentives or rebates for energy-efficient home improvements, potentially offsetting some of the initial cost.

Additionally, studies show that energy-efficient features like thermally broken windows can boost property value. This added value can be a significant return on investment when you decide to sell your home.

Maximizing Your Return

To truly maximize your investment in thermally broken windows, consider the following:

- Climate: In harsher climates, the energy savings are more pronounced, leading to a quicker payback period.

- Window Quality: Higher-quality windows with better thermal performance will deliver greater long-term savings.

- Installation: Proper installation is essential for peak energy efficiency and optimal window performance.

By carefully considering these factors and making well-informed decisions, you can maximize your return and enjoy the many benefits of thermally broken windows for years to come.

Installation Secrets for Maximum Performance

Getting the most out of your thermally broken windows isn't just about buying the highest quality; it's about installing them correctly. Proper installation is key to maximizing energy efficiency and protecting your investment. Let's explore the secrets to a successful installation, drawing insights from experienced installers and building science principles.

The Crucial Role of Proper Installation

Several factors impact the effectiveness of thermally broken windows. Precise sealing is paramount to prevent air leaks and maintain the thermal barrier. This involves using high-quality sealants and applying them correctly around the window frame. For more sealing tips, check out this helpful resource: Window and Door Sealing Tips for Better Home Comfort.

Insulation around the window opening is equally important. This helps minimize heat transfer through the surrounding walls. Proper flashing techniques are also crucial to prevent water damage, ensuring moisture is directed away from the window.

Common Installation Mistakes and How to Avoid Them

Even seasoned contractors can make mistakes that compromise window performance. One common error is inadequate sealing between the frame and the rough opening. This creates a thermal bridge, allowing heat to bypass the thermal break.

Another mistake is using the wrong insulation. Insulation with a lower-than-recommended R-value significantly reduces the window's effectiveness. Incorrect flashing can lead to water damage and costly repairs. For insights on precise measurements and meticulous sealing, take a look at this cabinet installation guide. While cabinet-focused, the principles apply to window installations as well.

Key Questions to Ask Your Installer

Before hiring an installer, ask specific questions. Inquire about their experience with thermally broken windows and their understanding of the technology. Discuss their sealing and insulation methods, request references, and check reviews.

Retrofitting vs. New Construction

Installation varies between retrofitting and new construction. In retrofits, careful removal of old windows and proper opening preparation are essential, including addressing existing damage. In new construction, coordination with other trades, like framers and insulators, is crucial.

Climate Considerations

Installation must account for climate. In colder climates, insulation and air sealing are paramount to prevent heat loss. In warmer climates, preventing heat gain and managing moisture are key. Choosing appropriate sealants and insulation for your climate is vital.

Building Type Considerations

Different building types have unique installation requirements. Commercial buildings often have different codes and regulations than residential installations. Larger window sizes in commercial projects may require specialized equipment. Understanding these challenges is essential for successful installation.

By understanding these installation secrets and asking the right questions, you can ensure your thermally broken windows deliver optimal performance and energy savings.

Ready to upgrade your home? Visit Gladiator Window and Doors to explore our selection of custom-made, thermally rated products, including extra-large sliding doors, pivot doors, bi-fold doors, panoramic doors, folding windows, and pergolas. Benefit from the lowest prices in the USA, backed by our Best Offer Guarantee.