Understanding Your Bifold Door System

A smoothly operating bifold door can truly open up a space. These systems, built with interconnected tracks, rollers, and pivot points, can sometimes require adjustments to maintain their seamless performance. This section explores the mechanics of bifold doors and explains why occasional adjustments are needed. Knowing how the top track and rollers interact, for instance, is essential for troubleshooting and fixing any issues that might arise.

Key Components and Their Functions

-

Top Track: The top track guides the rollers and controls the door's movement. Keeping it properly aligned is key for smooth operation.

-

Rollers: These small wheels glide along the top track, bearing the weight of the door panels. Adjusting the rollers often solves sticking or binding problems.

-

Pivot Points: Found at the top and bottom of each door panel, pivot points are what allow the doors to fold and unfold. They work together with the track and rollers to maintain proper alignment.

-

Tracks and Guides: While the top track guides the rollers, the bottom track and guides stabilize the doors and maintain proper floor clearance. Adjustments to these components often fix dragging issues.

Why Adjustments Are Necessary

Several factors can affect the alignment of your bifold doors. Normal wear and tear can loosen components over time. Also, changes in temperature and humidity can cause materials to expand and contract, impacting alignment.

Regular inspection and minor adjustments are often needed to keep your doors working smoothly. For more information on related topics, check out our blog sitemap.

The growing popularity of bifold doors further emphasizes the importance of understanding these systems. The global market reached $10.9 billion in 2024 and is expected to continue expanding. With more installations comes a greater need for proper adjustment techniques. Industry experts estimate that alignment problems account for 15–20% of service calls after installation. Learn more about the bifold door market.

Recognizing the Early Warning Signs

Catching early signs of misalignment can prevent small issues from becoming big headaches. A door that sticks, binds, or drags clearly indicates a potential alignment problem.

Even subtle changes, like uneven gaps between panels or increased noise, can signal a need for adjustment. Recognizing these early warnings allows for timely intervention, keeping your bifold doors operating flawlessly. Understanding how these components work together prepares you to handle common bifold door challenges.

Essential Tools and Prep: Setting Up For Success

Before tackling any bifold door adjustments, having the right tools and prepping the door are essential. This ensures a smooth and successful process. Just as a surgeon needs the correct instruments, you need the right tools for this task. Good preparation sets the stage for a job well done.

Gathering Your Toolkit

Having the right tools makes bifold door adjustments much easier. The specific tools depend on the adjustment's complexity and your door type. Basic adjustments may only require a few simple tools. More involved adjustments might need specialized equipment.

- Screwdrivers: Phillips and flathead screwdrivers are essential for adjusting screws and brackets.

- Adjustable Wrench: An adjustable wrench is useful for precise adjustments to pivot brackets and other hardware.

- Tape Measure: Accurately measure gaps between panels and check the overall door alignment with a tape measure.

- Level: A level helps ensure your doors are vertically and horizontally aligned, preventing future problems.

For specific tool recommendations in different situations, check out this resource: How to master bifold door adjustments with the right tools. Having the necessary tools ready will save you time and frustration.

Pre-Adjustment Inspection and Preparation

Inspecting your bifold doors before adjusting them is a crucial step that's often overlooked. Think of it like a doctor diagnosing a patient before prescribing treatment. This inspection helps identify problems and determine your adjustment strategy.

- Track Debris Removal: Clear any dirt, debris, or obstructions from the tracks to ensure smooth door operation. A clean track is fundamental for a well-functioning bifold door.

- Hardware Lubrication: Lubricate moving parts, like rollers and pivot points, to address sticking or squeaking. Silicone-based lubricants are generally recommended.

- Component Check: Inspect all components for wear and tear. Sometimes, replacing a part is a better solution than adjusting it. This prevents further issues and ensures long-term functionality.

These steps are vital for a successful bifold door adjustment. They make a potentially challenging task manageable. Proper preparation is the key to a smooth, long-lasting bifold door system.

Before we proceed to the adjustments themselves, let's review the essential tools for each type of adjustment. The following table outlines the necessary and optional tools, along with the skill level required for each task.

| Adjustment Type | Required Tools | Optional Tools | Skill Level |

|---|---|---|---|

| Tightening Loose Screws | Screwdriver (Phillips/Flathead) | None | Beginner |

| Aligning Door Panels | Level, Tape Measure | Shims | Intermediate |

| Adjusting Roller Height | Screwdriver, Adjustable Wrench | Pliers | Intermediate |

| Replacing Damaged Rollers | Screwdriver, Pliers | Hammer | Advanced |

| Track Alignment | Level, Screwdriver, Rubber Mallet | Shims | Advanced |

This table serves as a quick reference for the tools you'll need depending on the type of adjustment you're performing. Having these tools at the ready will streamline the process.

Safety First

Safety is paramount for any home improvement project. Always disconnect the power to the door if it's automated. This prevents accidental opening or closing. Also, wear appropriate safety glasses and gloves to protect yourself from potential hazards.

Top Track and Roller Magic: The Key Adjustments

The top track system is the core of bifold door adjustment. Mastering adjustments in this area can transform a sticky, troublesome door into a smoothly gliding one. This section offers a step-by-step guide on how professionals handle common bifold door problems. We'll concentrate on pinpointing the correct roller adjustments and using a specific sequence to avoid creating new issues while resolving existing ones.

Identifying the Right Adjustments

Before making any adjustments, diagnose the specific problem. A door that binds might require a roller height adjustment, while uneven gaps could indicate an alignment issue. Accurately identifying the problem helps you select the appropriate solution and avoids unnecessary adjustments. This careful approach saves time and prevents potential damage to the door system.

The Adjustment Process: A Step-by-Step Guide

The process flow below illustrates the typical steps for adjusting the top track and rollers of a bifold door. This infographic visualizes the process for adjusting the rollers and track, from initial inspection to final testing. It's crucial to follow these steps in order to achieve the best results and avoid making existing problems worse.

The process flow emphasizes the importance of systematic inspection, adjustment, and testing to ensure smooth bifold door operation. By following these steps, you can efficiently address issues without introducing new ones.

- Initial Inspection: Carefully examine the door's movement, noting any sticking, binding, or uneven gaps. This helps pinpoint the problem area.

- Locate Adjustment Screws: Find the screws on the top track brackets and rollers that control height and alignment. The infographic shows their typical locations.

- Height Adjustment: If the door drags or has uneven floor clearance, adjust the roller height using the corresponding screws.

- Alignment Adjustment: If gaps between panels are uneven, adjust the alignment screws on the track brackets.

- Testing and Fine-tuning: Test the door after each adjustment, opening and closing it fully to check for smooth operation. Fine-tune as needed with small, incremental adjustments.

You might be interested in: How to master further aspects of bifold door maintenance.

Height vs. Alignment Adjustments

Understanding the difference between height and alignment adjustments is key. Height adjustments mainly address vertical alignment and floor clearance. Alignment adjustments focus on the spacing between the door panels. Knowing when and how to use each type of adjustment is vital for a smoothly operating door. For instance, a dragging door needs a height adjustment, while inconsistent gaps between panels require an alignment adjustment.

Material Considerations and Long-Term Performance

The material of your bifold door significantly impacts how often adjustments are needed. Wooden doors, making up about 30% of installations, often require seasonal adjustments due to expansion and contraction from humidity changes. Aluminum and uPVC doors, experiencing market growth of over 5.9%, offer better dimensional stability. This trend toward lower-maintenance materials contributes to fewer required adjustments. However, improper installation still causes 25–30% of early performance problems, regardless of material. This underscores the importance of a correct initial setup and using adjustable hardware in a market projected to reach $10.9–$15.6 billion. Explore this topic further. This highlights the importance of getting it right from the beginning.

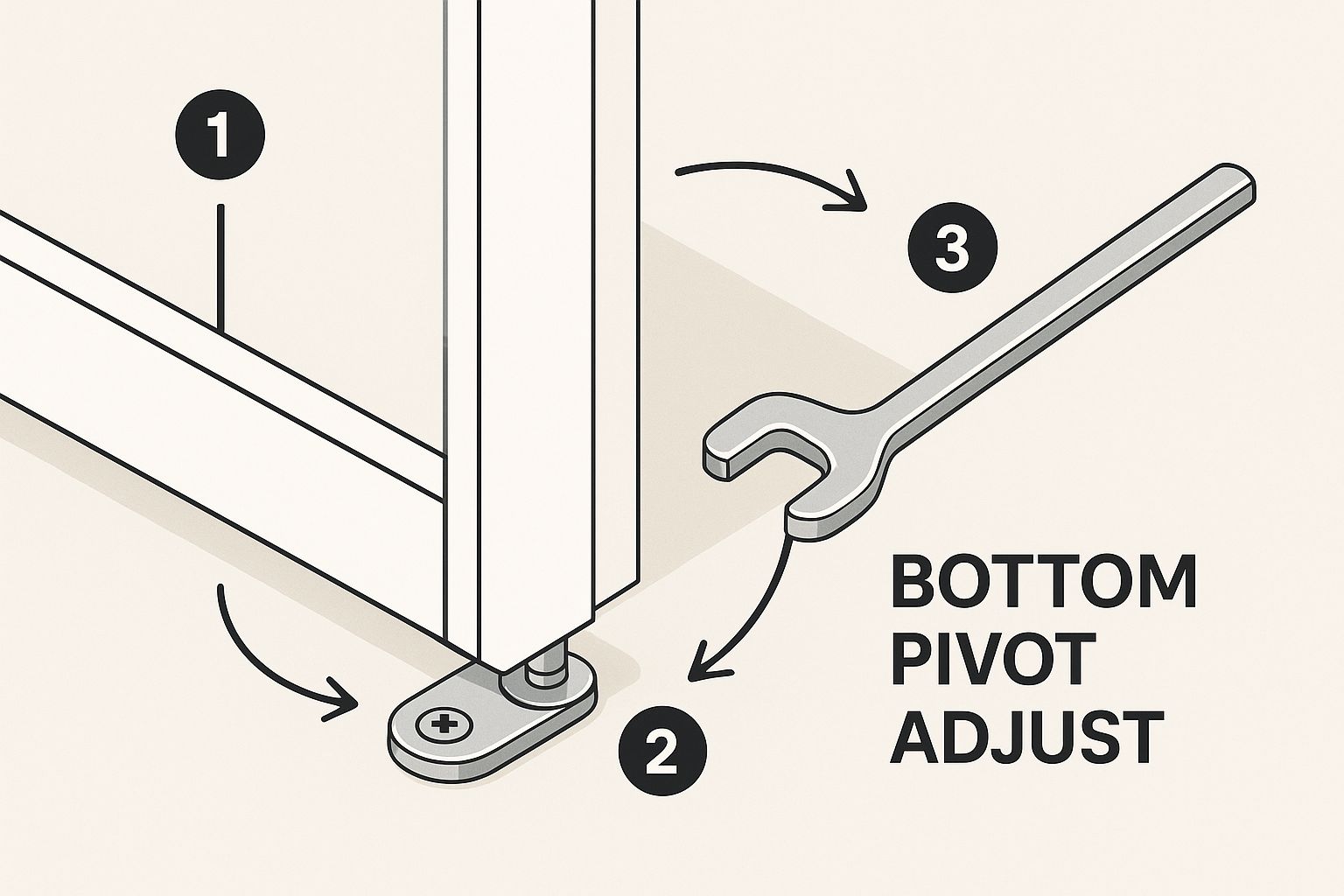

Bottom Pivot Perfection: Stability and Alignment

While the top track and rollers guide your bifold doors, the bottom components are crucial for stability and smooth operation. These often-overlooked parts are key to preventing dragging and ensuring effortless gliding. This section covers professional techniques for adjusting the bottom pivot pins and guide systems, allowing you to fine-tune your doors for optimal performance.

Understanding the Bottom Pivot and Guide System

The bottom pivot and guide system work together with the top track to control the door's path. The bottom pivot, usually a pin or wheel, anchors the door panel to the floor and allows rotation. The guide system, often a track or channel, prevents sideways movement and ensures smooth swinging. It acts like a rudder, providing directional stability.

Achieving Perfect Floor Clearance

One common issue is dragging. This often stems from an incorrectly adjusted bottom pivot. Perfect floor clearance means the door neither drags nor has excessive clearance, which can affect stability. This balance ensures smooth operation and prevents damage.

-

Raising the Pivot: If the door drags, raise the bottom pivot slightly. This usually involves turning an adjustment screw on the pivot. Small adjustments are key, as even slight changes impact movement.

-

Lowering the Pivot: If the door has too much clearance, lower the bottom pivot. Make gradual adjustments and test the door after each one.

Recognizing When Bottom Adjustments Are Needed

Sometimes, problems seemingly from the top track actually originate below. A binding or unevenly swinging door might need a bottom, not a top, adjustment. Careful diagnosis is crucial.

The Critical Relationship Between Top and Bottom Alignment

Top and bottom alignment are interconnected. A misaligned bottom pivot can disrupt the entire system, even with a perfect top track. Coordinated adjustments ensure smooth movement and prevent future problems.

-

Start with the Bottom: When addressing alignment, begin with the bottom pivot and guide. Ensure proper positioning before adjusting the top track.

-

Fine-Tuning: After adjusting the bottom, fine-tune the top rollers to synchronize the systems. This creates consistently smooth operation.

Before we discuss weatherstripping, let's look at common bifold door issues and their solutions:

Bifold Door Adjustment Problems and Solutions

This table outlines common problems, their causes, solutions, and prevention tips.

| Problem | Cause | Adjustment Solution | Prevention Tips |

|---|---|---|---|

| Door dragging on the floor | Bottom pivot too low | Raise the bottom pivot by turning the adjustment screw | Regularly check and adjust the bottom pivot |

| Excessive clearance between door and floor | Bottom pivot too high | Lower the bottom pivot | Ensure the floor is level and even |

| Door binding or sticking | Misaligned bottom pivot or guide | Adjust the bottom pivot and guide, ensuring proper alignment with the top track | Keep the track clean and free of debris |

| Uneven swinging | Bottom pivot not centered | Center the bottom pivot within the guide | Check for loose screws and tighten as needed |

By understanding these problems and solutions, you can keep your bifold doors operating smoothly.

Weatherstripping Considerations for Exterior Doors

For exterior doors, weatherstripping prevents drafts and maintains energy efficiency. When adjusting the bottom pivot, ensure the weatherstripping seals tightly against the threshold when closed. This prevents airflow and maintains insulation. A properly adjusted door with a good seal keeps the elements out and comfort in.

Multi-Panel Mastery: Synchronizing Door Movement

Multi-panel bifold doors create stunning, wide-open spaces. But their intricate design can present some unique challenges when it comes to adjustments. This section explores the specialized techniques professionals use to synchronize the movement of multiple panels, ensuring they operate smoothly and consistently.

Establishing the Reference Panel

The first step in adjusting these complex door systems is choosing a reference panel. This panel serves as the foundation for all other adjustments, similar to a cornerstone in construction. Usually, the panel nearest to the stationary jamb is the best choice. Make sure this panel is perfectly plumb and aligned within its track before moving on to the other panels. This creates a stable base for the entire system.

Creating Consistent Gaps

Maintaining uniform spacing between panels is essential for both visual appeal and proper function. Inconsistent gaps could indicate misalignment and might cause the doors to bind or stick. Professionals use precise measurements and careful adjustments to achieve consistent gaps across all panels. It's like aligning the teeth of a gear – each one must be perfectly positioned for the mechanism to work smoothly. A gap that's too wide, for instance, might signal a need to adjust the adjacent panel's rollers or pivot points.

Addressing Panel Collisions

Panels bumping into each other during operation is a common problem in multi-panel systems. This can stem from several issues, such as misaligned tracks, loose hardware, or incorrectly adjusted rollers. Professionals methodically inspect each connection, making minor adjustments to eliminate collisions and restore smooth operation. This often involves adjusting the height and alignment of individual panels in relation to the reference panel. Also, check the track for any obstructions that might be contributing to the problem.

Fine-Tuning for Precise Folding

Beyond simply opening and closing, each panel should fold neatly into its designated spot. This requires fine-tuning to ensure the panels stack evenly when fully open, which is especially important for larger doors with many panels. This meticulous process involves adjusting both the top rollers and bottom pivot points to achieve precise alignment, resulting in a compact and visually appealing stack when the door is fully open.

Lock Alignment for Security and Functionality

For doors equipped with locks, precise alignment is critical for proper engagement. A misaligned lock can create security risks and could even damage the door if forced. Professionals ensure that the locking mechanisms are perfectly aligned to prevent both security issues and potential damage. Even a slightly misaligned latch can prevent the bolt from engaging correctly, compromising the door's security. Market trends like North America's booming residential renovation market (valued at over $5 billion) and Europe's focus on energy efficiency highlight the importance of properly adjusted doors for maintaining thermal performance. The Asia-Pacific region is also seeing significant growth, with a 5.95% CAGR, further emphasizing the need for adjustments, especially in humid climates. While precise data on adjustment-related issues is limited, manufacturers estimate that 10–15% of warranty claims are related to these types of problems. This suggests a substantial service opportunity within the growing global market, projected to reach $15.6–$21.91 billion by 2033. More detailed statistics can be found here: https://www.thebusinessresearchcompany.com/report/bifold-doors-global-market-report.

You might also be interested in: How to master further aspects of bifold door systems. Achieving perfect synchronization in multi-panel bifold doors takes a methodical approach and attention to detail. By using these professional techniques, you can transform a clunky, troublesome door into a smoothly operating masterpiece.

Prevention Strategies: Maintaining Perfect Operation

The secret to a long-lasting and smoothly operating bifold door isn't constant adjustments. It's about preventing the need for adjustments in the first place! This involves understanding what causes misalignment and implementing proactive maintenance. Just like a well-maintained car, a well-maintained bifold door will operate smoothly for years to come.

The Seasonal Maintenance Calendar

Similar to how you change your car's tires seasonally, your bifold doors might benefit from a seasonal maintenance routine. This is especially important for wooden bifold doors, which are susceptible to humidity changes.

- Spring: Inspect and clean the tracks, removing any debris. Lubricate all moving parts.

- Summer: Check for warping or swelling due to heat and humidity. Adjust as needed.

- Autumn: Clean the tracks to remove leaves and debris. Check the weatherstripping on exterior doors.

- Winter: Lubricate moving parts to prevent sticking due to cold weather. Inspect for drafts and adjust weatherstripping as necessary.

This seasonal approach keeps your doors operating smoothly year-round.

Lubrication Best Practices

Lubrication is crucial for smooth bifold door operation. Using the right lubricant is key. Silicone-based lubricants are generally recommended. They provide long-lasting lubrication and won't attract dirt. Avoid oil-based lubricants, as these can gum up the tracks.

Recognizing Early Warning Signs

Catching potential problems early minimizes the need for major adjustments. Pay attention to these subtle signs:

- Sticking or Binding: This often indicates a problem with the rollers or track alignment.

- Uneven Gaps: This could signal a misalignment issue.

- Increased Noise: Squeaking or grinding sounds usually indicate a need for lubrication.

- Difficulty Opening or Closing: This might point to various problems, from misalignment to worn-out hardware.

Addressing these early signs can prevent more significant problems later. Learn more in our article about bifold door maintenance and troubleshooting.

Documenting Your Adjustment History

Keeping a record of your adjustments is incredibly helpful. Note the date, the adjustment made, and the reason. This log helps you identify patterns, like constantly adjusting the same roller, which could indicate a larger problem with the track. This information is invaluable for troubleshooting and determining when to call a professional.

Environmental Factors and Door Materials

Different door materials react differently to environmental changes. Wooden doors are more susceptible to expansion and contraction due to humidity, unlike aluminum and uPVC. Understanding these differences can help you anticipate potential adjustments. For example, in humid climates, you might expect to adjust wooden doors more frequently.

Professional Intervention: When to Call an Expert

While many adjustments can be DIY projects, some situations require professional help. If you've made multiple adjustments without success, or if you're unsure about a particular adjustment, contact a qualified door technician. They have the expertise and tools to handle complex issues.

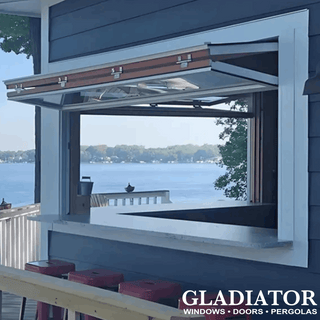

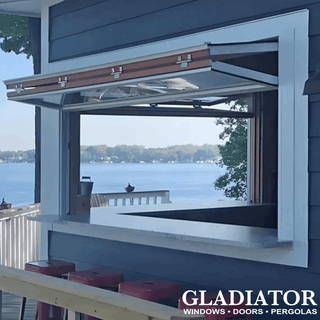

Ready for high-quality bifold doors? Visit Gladiator Window and Doors for the lowest prices and best warranty in the USA! We specialize in custom-made, thermally rated doors, including extra-large sliding, pivot, bifold, and panoramic doors. We also offer fully loaded pergolas. Choose Gladiator for unbeatable value and performance.