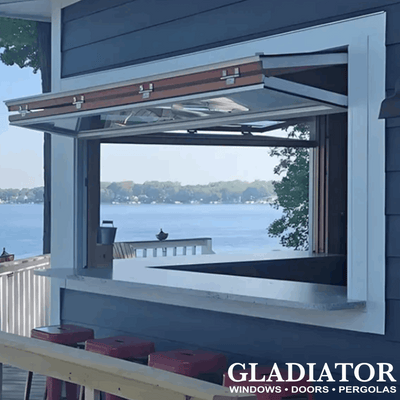

Why Sliding Door Maintenance Matters More Than You Think

Sliding doors bring a touch of elegance and practicality to any home, creating seamless transitions between indoor and outdoor spaces. But like anything used often, they need regular attention to stay in top shape. Overlooking sliding door maintenance can create problems beyond a sticky door, impacting your home's security, energy efficiency, and your finances.

The Hidden Costs of Neglect

A smoothly gliding sliding door signifies a well-maintained system. Ignoring seemingly small issues like a squeak or slight resistance can escalate into larger, costlier problems. Dirt and debris buildup in the tracks can wear down the rollers, causing jerky movements. Worn seals compromise insulation, letting drafts and moisture in and driving up energy bills.

Security and Energy Efficiency: More Than Just Smooth Operation

Proper maintenance directly affects your home's security. A sticky or difficult-to-operate door becomes an easy target for intruders. Maintaining secure locks and clear tracks ensures your door functions as a robust barrier. Furthermore, well-maintained seals are vital for energy efficiency. By preventing drafts, they maintain a consistent indoor temperature, easing the burden on your heating and cooling system, and saving you money. The global automatic sliding doors market, requiring regular maintenance, is projected to grow from $2.45 billion in 2024 to $3.28 billion by 2029 at a 5.9% CAGR. This growth highlights the increasing importance of these systems in various sectors like healthcare and retail. Find more detailed statistics here: Automatic Sliding Doors Market

Regional Considerations and Preventative Care

Your local climate influences your sliding door maintenance needs. Coastal, salty air requires more frequent cleaning and lubrication to combat corrosion. Areas with significant temperature swings can cause seals to expand and contract, potentially leading to air leaks. You might be interested in: Our blog articles. A proactive maintenance routine tailored to your region is essential. Addressing small issues early prevents major problems and extends the lifespan of your doors.

Regular sliding door maintenance is a worthwhile investment. It ensures smooth operation, enhances security, improves energy efficiency, and protects your investment over time. By understanding the importance of preventative care and adopting a proactive approach, you can enjoy the benefits of well-functioning sliding doors for years to come.

The Essential Toolkit: What Pros Use and You Should Too

Having the right tools for sliding door maintenance is key. It's not about having the priciest equipment, but rather the correct tools for a smooth and efficient maintenance process. Choosing the right tools can make all the difference between a quick fix and a frustrating afternoon.

Gathering Your Arsenal

You don't need a professional's complete set of tools, but some essentials are crucial. For cleaning the tracks, a stiff-bristled brush, a vacuum with a crevice attachment, and a scraper (like a putty knife) are essential. These tools help remove dirt and debris buildup. A silicone-based lubricant is recommended for lubrication, as it's long-lasting and resists attracting dirt. For further guidance, see our article on how to master sliding door maintenance.

- Stiff-bristled brush: Removes stubborn dirt and debris.

- Vacuum with crevice attachment: Cleans hard-to-reach areas.

- Scraper (putty knife): Lifts caked-on grime.

- Silicone-based lubricant: Ensures smooth operation.

To help you assemble everything you might need, here’s a handy table outlining essential and optional tools, along with some product recommendations.

Essential Sliding Door Maintenance Tools

| Maintenance Task | Required Tools | Optional Tools | Recommended Products |

|---|---|---|---|

| Cleaning the Track | Stiff-bristled brush, Vacuum with crevice attachment, Scraper | Cleaning solution, Shop towels | WD-40 Specialist Silicone Lubricant, 3M General Purpose Scraper, OXO Good Grips Deep Clean Brush Set |

| Lubricating the Track | Silicone-based lubricant | Applicator straw | WD-40 Specialist Silicone Lubricant |

| Inspecting Rollers | Flashlight | Screwdriver | – |

| Checking Weatherstripping | – | Scissors, Replacement weatherstripping | Frost King Heavy Duty Rubber Weatherstrip Seal |

This table offers a quick reference guide for assembling your sliding door maintenance kit, allowing you to easily gather the necessary tools.

The Sliding Door Maintenance Process

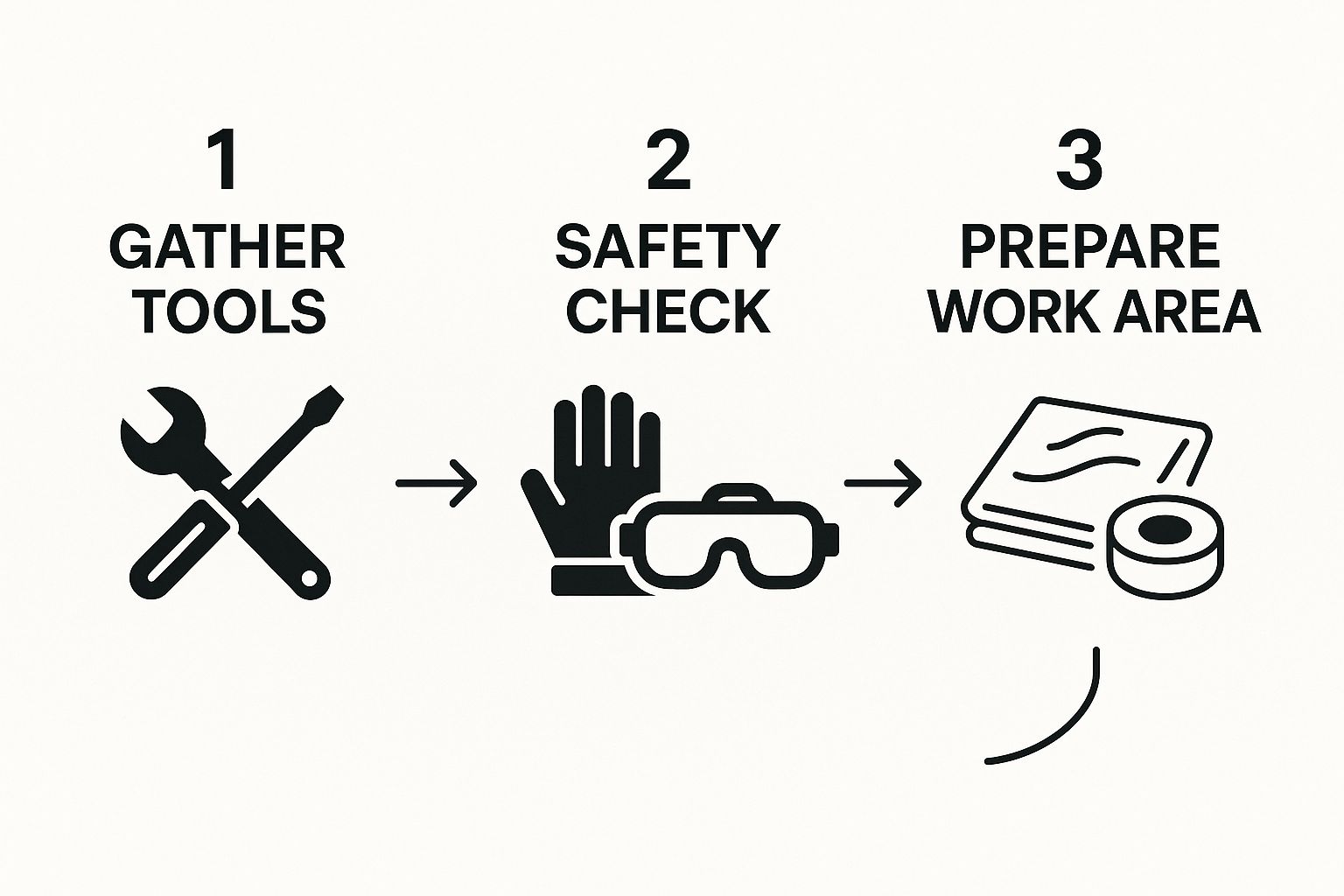

Maintaining your sliding doors is straightforward. The process flow below outlines the steps for effective maintenance.

-

Cleaning the Track: Begin by cleaning the tracks. Use the brush and vacuum to remove loose debris. A scraper can be used to remove stubborn grime.

-

Lubricating the Track: Apply silicone-based lubricant to the clean tracks. This allows for smoother operation and reduces friction.

-

Inspecting Rollers: Check the rollers for any signs of damage or wear. Consider replacing them if necessary.

-

Checking Weatherstripping: Inspect the weatherstripping for damage and a proper seal. Replace it if it's worn to maintain energy efficiency.

The process flow illustrates the four crucial steps for sliding door maintenance: cleaning, lubricating, inspecting rollers, and checking weatherstripping. The order of these steps is important. Cleaning before lubricating ensures the lubricant's effectiveness.

Safety First

While this is a relatively simple task, prioritize safety. Be cautious when using tools, especially scrapers. Keep children and pets away from the work area.

Track Mastery: Cleaning and Lubrication Techniques

The track of your sliding door is essential for smooth operation. However, it often gets neglected, accumulating dirt and grime that can affect its performance. This section covers professional cleaning and lubrication techniques to keep your sliding door tracks in optimal condition.

Cleaning Different Track Materials

Different track materials need specific cleaning methods. For aluminum tracks, use a stiff-bristled brush and a vacuum to remove loose debris. For stainless steel tracks, a non-abrasive cleaner will prevent scratches. No matter the material, avoid harsh chemicals that could damage the track's finish. For more tips, check out this resource: How to Master Sliding Door Maintenance. This ensures your cleaning actually helps, rather than harms, your door.

Effective Cleaning Methods

Begin by removing loose debris with a brush and vacuum. For stubborn grime, carefully use a scraper to avoid scratching the track. Warm water and mild dish soap can also be effective. Ensure the tracks are completely dry after cleaning to prevent rust and corrosion. This simple process can significantly extend the life of your tracks and rollers.

The Science of Lubrication

Lubrication is key for smooth door operation. Silicone-based lubricants are ideal for sliding door tracks due to their longevity, resistance to dirt buildup, and ability to withstand temperature changes. Avoid oil-based lubricants as they attract dirt and can gum up the tracks. Proper lubrication minimizes friction, reducing wear and tear on the rollers and ensuring effortless gliding. The rise of touchless entry systems has led to the integration of AI-driven predictive maintenance tools in modern automatic sliding doors. These tools analyze usage patterns and component wear, leading to a 15-20% reduction in maintenance costs through early fault detection. Learn more about this technology here.

Addressing Hard-to-Reach Areas and Rust

Cleaning hard-to-reach areas of the track can be tricky. A cotton swab dipped in cleaning solution can be useful, or a toothbrush can scrub tight corners. For rust or corrosion, carefully use a wire brush to remove the buildup, followed by a rust-inhibiting primer to prevent it from coming back. This attention to detail ensures the entire track contributes to smooth door operation.

Establishing a Maintenance Schedule

Regular maintenance prevents significant problems. Cleaning and lubricating the tracks every few months, or more often in high-traffic areas, is recommended. Regular inspections can catch potential issues early, saving you time and money down the road. A consistent maintenance schedule is a worthwhile investment in the longevity and performance of your sliding doors.

Roller Revival: Maintenance Secrets for Smooth Gliding

Those tiny rollers carry the weight of your sliding door, ensuring it opens and closes smoothly. Yet, they're often overlooked until a problem arises. This guide explores the essentials of roller maintenance, from recognizing wear and tear to replacing them effectively.

Recognizing the Signs of Roller Fatigue

Just like tires on a car, sliding door rollers wear down with use. Squeaking, grinding, or popping sounds are early indicators of roller problems. If the door is difficult to open or close, or exhibits a jerky, uneven movement, it might be time to inspect your rollers. Addressing these issues early can prevent further damage and keep your door operating smoothly.

Roller Removal and Replacement: A Professional Touch

Removing rollers without damaging the door panel requires skill and precision. Professionals utilize specialized tools to carefully disengage the rollers from the track. This protects the door and frame from unnecessary stress. When choosing replacements, consider the roller material and design. Nylon, steel, and plastic each offer unique benefits and drawbacks related to durability and performance. Roller designs, whether single, tandem, or ball bearing, impact the door’s weight capacity and smoothness of operation. Replacing worn rollers requires careful installation, ensuring proper alignment and secure placement for optimal performance.

Fine-Tuning for Optimal Performance: The Importance of Adjustments

Adjusting rollers is a crucial step many DIYers overlook. Fine-tuning the height and tension ensures even weight distribution and smooth gliding. Adjustment screws, usually located on the roller assembly or the door frame, facilitate this process. Proper adjustments can significantly improve the door's operation, turning a sticky, difficult door into one that glides effortlessly. Keeping your screens clean also contributes to their overall appearance and longevity. Find helpful cleaning tips at Cleaning Tips: How to Clean Your Security Screens.

DIY vs. Professional: Knowing When to Call for Help

Simple maintenance tasks, like cleaning and lubrication, are usually manageable for homeowners. However, replacing rollers, especially on heavier doors, or performing complex adjustments, often requires professional expertise. This ensures the job is done correctly and safely, minimizing potential damage. Knowing when to call a professional can save time, money, and prevent future headaches.

To help you choose the right rollers, consult the comparison table below.

Sliding Door Roller Comparison Guide

This table outlines the different types of sliding door rollers, their ideal applications, lifespan, maintenance needs, and average costs.

| Roller Type | Best For | Expected Lifespan | Maintenance Needs | Average Cost |

|---|---|---|---|---|

| Nylon | Lighter doors, quiet operation | 5-7 years | Regular cleaning and lubrication | $5-$10 per roller |

| Steel | Heavier doors, high durability | 10-15 years | Less frequent maintenance | $10-$20 per roller |

| Ball Bearing | Smooth operation, heavy doors | 15+ years | Minimal maintenance | $20-$30 per roller |

Key Takeaways: This table offers a general overview; actual prices may vary. Consult a professional for tailored recommendations based on your door type and usage. Choosing the correct roller type and ensuring proper installation and maintenance are essential for the smooth and long-lasting operation of your sliding doors.

Weather Protection: Seal Maintenance Made Simple

Weatherstripping acts as your sliding door's initial shield against harsh weather. Maintaining these seals properly is essential for energy efficiency and safeguarding your entire door system. This frequently neglected aspect of sliding door upkeep can prevent expensive repairs later.

Evaluating Weatherstripping Condition

Before starting any maintenance, assess the current state of your weatherstripping. Inspect it for any visible signs of damage like cracks, tears, or gaps. Also, check for areas where the seal isn't fully contacting the door frame. These gaps allow drafts and moisture to infiltrate, reducing energy efficiency and potentially harming your door. A simple test involves closing the door on a piece of paper. If the paper pulls out easily, the seal requires attention. This easy check helps identify problems early.

Material-Specific Approaches: Compression vs. Brush Seals

Different seal materials require specific care. Compression weatherstripping, often made of rubber or foam, creates a seal by compressing against the frame. Ensure the material remains pliable and applies sufficient pressure. Brush seals, commonly located at the bottom of the door, use bristles to block drafts and debris. Check for missing or damaged bristles and clean them regularly to prevent buildup. For more information, check out our article on different types of doors and windows. Understanding each material's unique needs will guide you toward the correct maintenance techniques.

Seal Removal and Installation Best Practices

When replacing weatherstripping, careful removal is key. Use a putty knife to gently pry the old seal away, avoiding damage to the door or surrounding areas. Before installing the new seal, clean and dry the surface to ensure proper adhesion. Follow the manufacturer's instructions precisely when applying the new weatherstripping for a tight and effective seal. Accurate installation is crucial for optimal performance.

Climate Considerations and Maintenance Schedules

Your local climate significantly impacts seal selection and required maintenance frequency. In hotter climates, choose weatherstripping resistant to high temperatures and UV exposure. In colder climates, prioritize seals designed for insulation and draft prevention. Regardless of location, regularly inspect and clean your weatherstripping to maintain its effectiveness. Harsher climates may necessitate more frequent checks and replacements. This proactive approach can prevent common issues like water damage and seal deterioration.

Troubleshooting Common Seal Issues

Addressing issues like drafts, water leaks, and worn seals requires careful troubleshooting. For drafts, examine the weatherstripping for gaps and replace any damaged sections. For water infiltration, check the drainage around your door and confirm the seals form a tight barrier. If the seals are deteriorated, replacement is the best course of action. By understanding these common problems, you can take the right steps to maintain a comfortable and energy-efficient home.

Perfect Alignment: Pro-Level Adjustment Techniques

Even with regular maintenance, sliding doors might eventually need adjustments, especially after prolonged use or harsh weather. This section outlines professional methods for diagnosing and fixing alignment problems, transforming a sticky door into one that operates smoothly.

Diagnosing the Root Cause of Misalignment

Professionals don't just address the obvious issue; they pinpoint the underlying cause. This means thoroughly examining the rollers, tracks, and even the surrounding structure. A door sticking at the top could point to a roller problem. Difficulty sliding at the bottom might indicate track issues or even a slight shift in the foundation. Grasping these differences is key for effective repairs.

Adjustment Points: From Residential to Commercial Doors

Different door systems have unique adjustment points. Residential patio doors commonly feature adjustable screws on the rollers themselves or on the door frame’s bottom track. Commercial doors often have more complex mechanisms, sometimes requiring access to the internal hardware. Locating these adjustment points is the first step towards correcting alignment.

Making Incremental Changes: The Art of Fine-Tuning

Adjustments should always be gradual. Small turns of a screw can have a significant impact. Over-tightening or loosening can lead to further problems or damage components. Even a tiny adjustment to the roller height can drastically improve door operation. This precise approach is crucial for perfect alignment. Maintaining effective seals around the door may also involve inspecting the adjacent siding and potentially contacting siding repair specialists.

Utilizing Alignment Tools and Prioritizing Safety

Professionals often use specialized alignment tools for accurate adjustments, similar to levels used in construction, to maintain proper vertical and horizontal positioning. Safety is paramount when handling large, heavy doors. Always support the door properly during adjustments to prevent accidents. Remember to use appropriate safety glasses and gloves for personal protection.

Troubleshooting Stubborn Doors and Seasonal Shifts

Sometimes, doors resist typical adjustments. This might suggest a more serious issue like worn rollers, damaged tracks, or even structural problems with the building. In these situations, consulting a professional is advised. Seasonal temperature fluctuations cause materials to expand and contract, impacting door alignment. Regular adjustments, especially during significant temperature changes, maintain consistent performance year-round, particularly in areas with dramatic seasonal shifts.

DIY or Call the Pros? Making the Right Maintenance Decision

Knowing when to tackle sliding door maintenance yourself and when to bring in a professional can save you time, money, and a lot of frustration. This guide will help you make smart choices based on your individual needs.

Evaluating Repair Complexity

Simple jobs like cleaning the tracks and lubricating the rollers are usually pretty easy for DIYers to manage. However, more complicated problems, like replacing rollers or dealing with significant alignment issues, often call for professional help. For example, misaligned doors can sometimes indicate underlying structural problems that are beyond the scope of a typical homeowner's toolbox. Learn more in our article about sliding door maintenance. This information helps you assess what you can realistically handle and avoid accidentally making things worse.

Recognizing Warning Signs

Some issues definitely signal the need for a professional. This includes structural damage, like a warped frame or problems with the surrounding wall. Specialized system failures, such as broken locking mechanisms or damaged automated components, also demand expert attention. And of course, if you’re not comfortable using tools or are unsure about the repair process, it’s always best to call a professional. This proactive approach can prevent minor issues from escalating into major headaches.

Choosing Qualified Service Providers

When you're hiring a professional, make sure you ask the right questions. Find out about their experience with sliding doors, their licensing and insurance, and don’t hesitate to request references. Reputable service providers are always happy to share this information. Getting multiple quotes will help you compare prices and services, ensuring you get the best value. Doing your research upfront will give you confidence that you’re working with qualified and trustworthy people.

Cost Expectations for Different Maintenance Needs

Different maintenance tasks have different price tags. Basic cleaning and lubrication might run you between $50-$100. Replacing rollers can range from $100-$300 depending on the door size and the type of roller. More complex repairs that involve structural work can cost $500 or more. Knowing these cost ranges can help you budget effectively and avoid unexpected expenses.

Preventative Professional Services

For high-traffic or specialized doors, think about setting up regular professional maintenance. Routine inspections and servicing by skilled technicians can catch potential problems early, extending the lifespan of your doors and preventing costly repairs down the road. This preventative approach is especially beneficial for commercial properties or homes where sliding doors get a lot of use. Essentially, investing in preventative maintenance can save you money over time.

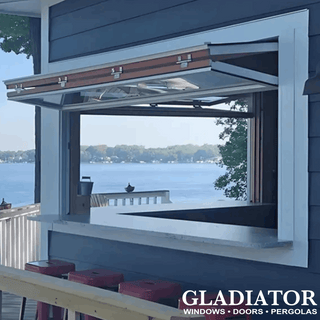

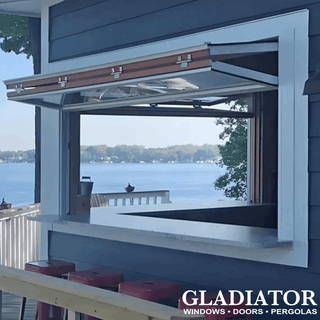

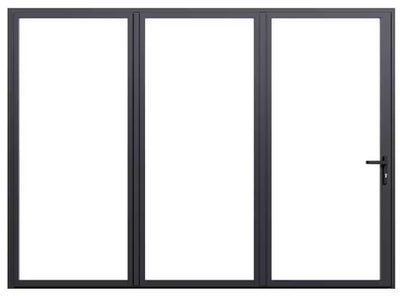

Ready to upgrade your sliding doors or need expert help with maintenance? Gladiator Window and Doors offers high-quality, custom-made doors at the lowest prices in the USA. We specialize in extra-large sliding doors, pivot doors, and more, with a best offer guarantee you won't find anywhere else. Visit us today!